Palletizer and MES docking scheme

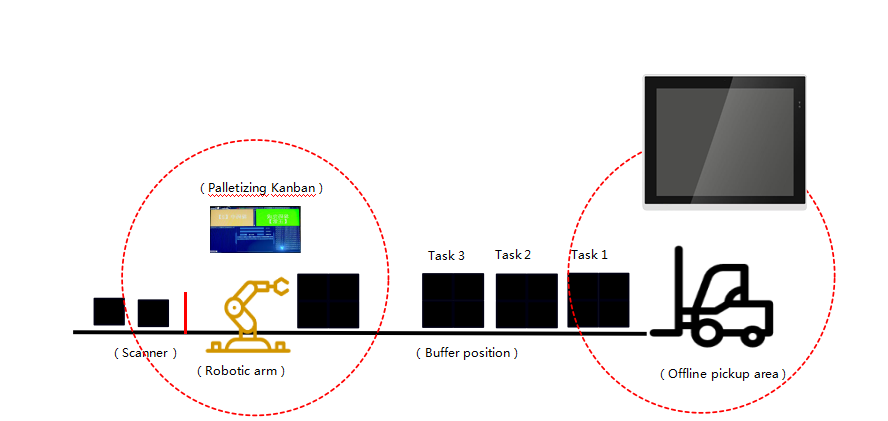

In large-scale production enterprises, improving the automation of industrial assembly lines is essential to strengthen capital utilization, reduce labor intensity and improve quality. The project develops and transforms palletizer PLC programs, develops warehouse management systems, purchases on-board computers and Informatization hardware equipment such as TV billboards realizes informatization warehouse management, integrates the front-end and back-end informatization system of finished products offline, realizes the visualization of the whole process of real logistics and information flow of direct orders, achieves rapid turnover of finished products, and improves customer service quality Purpose; the following figure illustrates:

Project composition:

Serial number

Features

project description

Remarks

1

Finished product offline palletizing

Realize the finished products to be palletized according to the order model, and develop the palletizing board to connect with MES

2

Palletizing robot palletizing information collection PPC-1701

Palletizing information collection interacts with the MES system to form the relationship between production barcodes and pallet positions

3

Industrial Tablet PPC-1201

Installed on the gripping truck for the whole stack of goods warehousing operation

4

Finished product warehouse visual management BOX-5021+ large visual screen

Increase the finished product warehouse TV billboard

5

Finished product warehouse PDA storage

Achieve mobile manual warehousing and abnormal discharge of finished products

1. Finished product offline palletizing

Analyze the barcode information by scanning the code to identify the order type and product model; synchronously transform the palletizer program to control the palletizer to distinguish the order and model for palletizing; when the palletizing is abnormal, the alarm device is triggered to guide manual processing;

2. Palletizing information collection of palletizing robot

(1) The palletizer generates a stack position number 001 after stacking a stack;

(2) Get the palletizing robot to stack 001 left or right;

(3) Obtain the information of the stacked number of left and right stack positions;

(4) The information in Article 1, 2 and 3 can be combined in any combination to communicate with the MES system through the interface;

(5) It is necessary to be able to store palletizing combination information for more than 3 days;

(6) The palletizing board can display the order product information, the left and right palletizing numbers, and provide guidance on the clamping sequence;

(7) The pick-up point grating senses the goods to be taken away, and the information is fed back to the palletizing billboard. The color change of the corresponding pallet number indicates that the goods have been picked up.

Categories

New Products

P15RW-J1 is a 15 inch fanless industrial tablet computer Read More

M30 is a fanless, low-power, high-performance embedded machine Read More

IPC-6056B is a seven-slot compact wall hanging machine On GeForce RTX™ 3090 Ti GAMING 24G graphics card Read More

The M80 series is a fanless, low-power, high-entry machine Read More

M75 is a fanless, low-power, high-performance embedded machine Read More

© Copyright: 2025 GUANGZHOU XIYANG ELECTRONIC CO.,LTD All Rights Reserved.

IPv6 network supported

Contact us

9th Floor, Building 1, Liandong Digital Valley, Knowledge City, Huangpu District, Guangzhou City, Guangdong Province, China

9th Floor, Building 1, Liandong Digital Valley, Knowledge City, Huangpu District, Guangzhou City, Guangdong Province, China

ImgWechat QR Code

ImgWechat QR Code