Intelligent Vision—The application scheme of industrial computer in machine vision system

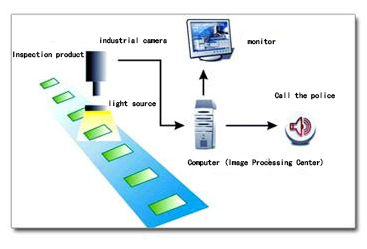

Machine vision is the "eye" of industrial automation, mainly composed of industrial cameras, light sources, industrial computers and corresponding image analysis software systems.

The working principle of machine vision is very simple. It is very similar to a single-function industrial robot. For example, it uses a camera to obtain the image of the detected object, and the special light source enables the features of the detected object to be enhanced in the image, such as size features, surface defects Features etc.

The images with clear characteristics are transmitted to the industrial computer at a high speed, and the characteristics are calculated by professional image analysis and processing software. According to the calculation results, the industrial computer can control the actuator to perform classification, rejection, alarm and other actions. If you compare it with humans, then cameras are like human eyes, industrial computers are like human brains, and software is like human thoughts. Then the actuators are like human hands and feet. In fact, the machine vision system is like a person with fast thinking, quick actions, and tirelessness.

Advantages of industrial computer:

Take IPC-6041 industrial computer as an example

Fast speed: The surface of strip steel moving at 1000m per minute can be fully inspected with an accuracy of 0.1mm, and the size of complex parts can be precisely measured and collected at a speed of thousands of pieces per minute.

Stable quality: The biggest drawback of manual inspection is that the quality is unstable, while the Yanhong industrial computer does not. The Yanhong industrial computer has the characteristics of reliability and stability. The machine vision can work uninterrupted for 24 hours with the set tasks, and ensure that the product inspection is complete.

Unrestricted by the environment: Humans cannot work in environments such as high temperatures and small spaces in industrial production, but machine vision is not restricted.

High precision: For the quality inspection of very small electronic components, connectors, etc., workers often need to use microscopes and other means, and the efficiency is low, while machine vision can quickly measure any small size with the help of high magnification lenses.

In recent years, with the rapid development of industrial computer technology, relying on the strong support of industrial computer, machine vision technology is increasingly being applied to the online inspection of industrial production, realizing fast and full inspection of product quality without omission, and then achieving Zero defect of product quality. At present, machine vision is mainly used in surface quality inspection, size measurement, target positioning, target recognition, target comparison, etc. The fields involved include the production of steel, non-ferrous metals, plastics, glass, textiles, paper, electronics, and precision parts.

Categories

New Products

P15RW-J1 is a 15 inch fanless industrial tablet computer Read More

M30 is a fanless, low-power, high-performance embedded machine Read More

IPC-6056B is a seven-slot compact wall hanging machine On GeForce RTX™ 3090 Ti GAMING 24G graphics card Read More

The M80 series is a fanless, low-power, high-entry machine Read More

M75 is a fanless, low-power, high-performance embedded machine Read More

© Copyright: 2025 GUANGZHOU XIYANG ELECTRONIC CO.,LTD All Rights Reserved.

IPv6 network supported

Contact us

9th Floor, Building 1, Liandong Digital Valley, Knowledge City, Huangpu District, Guangzhou City, Guangdong Province, China

9th Floor, Building 1, Liandong Digital Valley, Knowledge City, Huangpu District, Guangzhou City, Guangdong Province, China

ImgWechat QR Code

ImgWechat QR Code