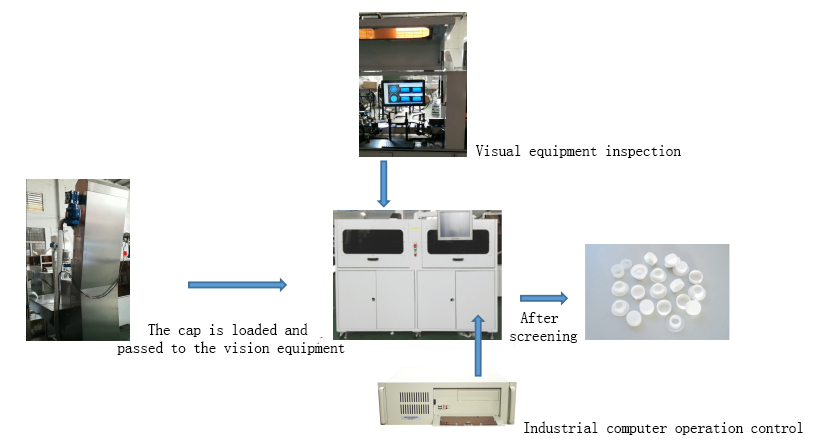

Bottle cap visual automatic inspection machine

The visual inspection system for bottle caps is a software system that replaces manual inspection, cracks, surface layer integrity, dents, etc. The system consists of five parts: industrial camera (6), industrial lens, visual inspection light source, industrial computer and VISION PRO (a design module provided by National Instruments for visual development), which can effectively improve the inspection speed and accuracy of the production line , Greatly improve output and quality, reduce labor costs, and prevent misjudgments due to eye fatigue.

Advantages of Yanhong Industrial Computer

Take IPC-6041 industrial computer as an example

Fast speed: 800 to 1000 bottle cap surface defects are detected per minute.

Stable quality: The biggest drawback of manual inspection is that the quality is unstable, and Yanhong industrial computer will not. Yanhong industrial computer has the characteristics of reliability and stability. The machine vision can work uninterruptedly for 24 hours with the set tasks, and ensure that the product inspection is not missed.

Unrestricted by the environment: Humans cannot work in environments such as high temperatures and small spaces in industrial production, but machine vision is not restricted.

Categories

New Products

P15RW-J1 is a 15 inch fanless industrial tablet computer Read More

M30 is a fanless, low-power, high-performance embedded machine Read More

IPC-6056B is a seven-slot compact wall hanging machine On GeForce RTX™ 3090 Ti GAMING 24G graphics card Read More

The M80 series is a fanless, low-power, high-entry machine Read More

M75 is a fanless, low-power, high-performance embedded machine Read More

© Copyright: 2025 GUANGZHOU XIYANG ELECTRONIC CO.,LTD All Rights Reserved.

IPv6 network supported

Contact us

9th Floor, Building 1, Liandong Digital Valley, Knowledge City, Huangpu District, Guangzhou City, Guangdong Province, China

9th Floor, Building 1, Liandong Digital Valley, Knowledge City, Huangpu District, Guangzhou City, Guangdong Province, China

ImgWechat QR Code

ImgWechat QR Code